Decoding The 410A Refrigerant Strain Chart: A Complete Information

Decoding the 410A Refrigerant Strain Chart: A Complete Information

Associated Articles: Decoding the 410A Refrigerant Strain Chart: A Complete Information

Introduction

On this auspicious event, we’re delighted to delve into the intriguing matter associated to Decoding the 410A Refrigerant Strain Chart: A Complete Information. Let’s weave fascinating info and supply recent views to the readers.

Desk of Content material

Decoding the 410A Refrigerant Strain Chart: A Complete Information

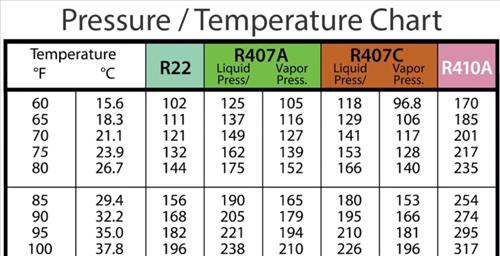

R-410A, a hydrofluoroolefin (HFO) mix, has grow to be a ubiquitous refrigerant in fashionable air con and refrigeration programs, largely changing R-22 resulting from its superior vitality effectivity and decrease environmental affect (although nonetheless a potent greenhouse fuel). Understanding its pressure-temperature relationship is essential for environment friendly operation, troubleshooting, and secure upkeep of those programs. This text delves deep into the intricacies of the 410A refrigerant strain chart, explaining its interpretation, utility, and the components influencing its accuracy.

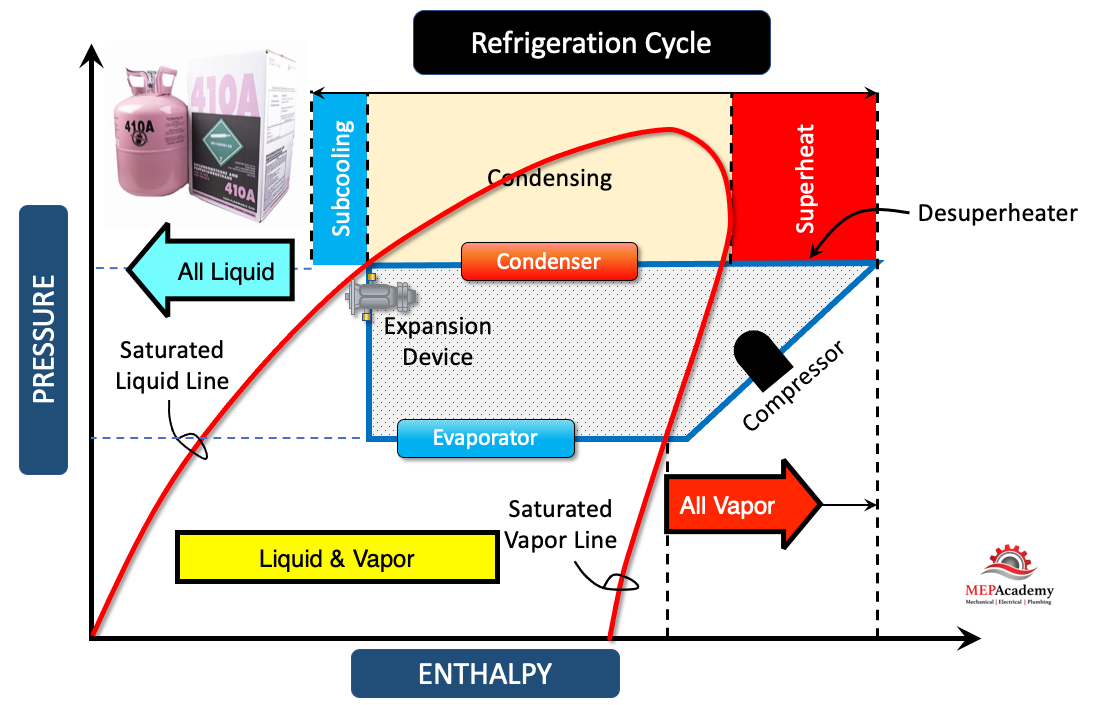

Understanding the Strain-Temperature Relationship in Refrigerant Methods

Refrigerant programs function based mostly on a thermodynamic cycle that leverages the pressure-temperature relationship of the refrigerant. Because the refrigerant adjustments phases (from liquid to vapor and vice versa), its strain and temperature change predictably. This relationship is key to understanding how a refrigeration system works and is graphically represented in a pressure-temperature chart. For R-410A, this chart exhibits the saturation strain (the strain at which the refrigerant adjustments section at a given temperature) at varied temperatures.

The 410A Strain-Temperature Chart: Key Parts and Interpretation

A typical 410A pressure-temperature chart shows two most important curves:

-

Saturation Strain Curve: This curve represents the strain at which R-410A exists as a saturated liquid-vapor combination. Factors alongside this curve point out the coexistence of liquid and vapor phases. Above this curve, the refrigerant is superheated vapor; beneath, it is subcooled liquid.

-

Temperature Axis (X-axis): This axis represents the temperature of the refrigerant, often expressed in levels Fahrenheit (°F) or Celsius (°C).

-

Strain Axis (Y-axis): This axis represents absolutely the strain of the refrigerant, usually expressed in kilos per sq. inch (PSI) or kilopascals (kPa).

Studying the Chart:

To make use of the chart successfully, you might want to know the refrigerant temperature. Find this temperature on the horizontal (temperature) axis. Then, hint a vertical line upwards till it intersects the saturation strain curve. The purpose of intersection signifies the saturation strain of R-410A at that particular temperature.

Sensible Purposes of the 410A Strain-Temperature Chart:

The chart serves a number of important functions in refrigeration and air con:

-

Troubleshooting: By measuring the strain and temperature at varied factors within the system (e.g., suction line, liquid line), technicians can rapidly establish potential issues. A strain studying considerably larger or decrease than the chart’s indication for a given temperature suggests points like refrigerant leaks, restricted stream, compressor malfunction, or condenser/evaporator issues.

-

Charging the System: The chart is crucial for precisely charging the system with the right amount of refrigerant. Overcharging or undercharging can severely affect effectivity and efficiency. Technicians use the chart to find out the anticipated strain based mostly on the system’s temperature and evaluate it to the precise strain readings.

-

System Efficiency Analysis: The chart helps assess the system’s general efficiency. Deviations from the anticipated pressure-temperature relationship can point out inefficiencies, requiring additional investigation and potential repairs.

-

Security: Understanding the pressure-temperature relationship is essential for security. Excessive-pressure circumstances can result in harmful system failures. The chart helps technicians perceive the strain limits and take needed precautions.

Elements Affecting the Accuracy of the Strain-Temperature Chart:

A number of components can affect the accuracy of strain readings and, consequently, the interpretation of the chart:

-

Ambient Temperature: The ambient temperature considerably impacts the system’s working strain. Greater ambient temperatures usually end in larger pressures.

-

System Design and Parts: The precise design of the refrigeration system, together with the kind and dimension of elements (compressor, condenser, evaporator), can affect strain readings.

-

Refrigerant Purity: Contaminants within the refrigerant can alter its pressure-temperature relationship.

-

Elevation: Altitude impacts atmospheric strain, which, in flip, influences the system’s working strain. At larger altitudes, the strain will probably be decrease for a given temperature.

-

Measurement Accuracy: The accuracy of the strain gauges and temperature sensors used is important for acquiring dependable readings. Calibration and common upkeep of those devices are important.

-

Superheat and Subcooling: The chart represents saturation circumstances. In real-world functions, the refrigerant is often superheated within the suction line and subcooled within the liquid line. These circumstances should be thought of when deciphering the chart. Superheat and subcooling are essential for optimum system effectivity and are measured individually and added to the saturation strain studying.

Past the Fundamental Chart: Superior Concerns

Whereas a easy pressure-temperature chart gives a very good place to begin, extra refined instruments and issues are needed for exact system evaluation:

-

Refrigerant Combination Conduct: R-410A is a zeotropic mix, that means its elements have completely different boiling factors. This impacts its pressure-temperature relationship in comparison with azeotropic refrigerants (these with a relentless boiling level). The composition of the mix should be thought of for correct readings.

-

Software program and Simulation Instruments: Superior software program packages can simulate refrigerant conduct beneath varied circumstances, offering extra detailed analyses than easy charts. These instruments typically incorporate extra complicated equations of state to account for the particular properties of R-410A.

-

Psychrometric Charts: For air con functions, psychrometric charts, which contemplate humidity, are sometimes used along with the pressure-temperature chart for a extra full understanding of system efficiency.

Security Precautions when Working with R-410A:

R-410A, whereas much less dangerous to the ozone layer than R-22, continues to be a potent greenhouse fuel and requires cautious dealing with. All the time observe these security pointers:

-

Correct Private Protecting Tools (PPE): Put on applicable security glasses, gloves, and clothes when working with R-410A.

-

Air flow: Guarantee satisfactory air flow within the work space to forestall the buildup of refrigerant vapors.

-

Leak Detection: Use applicable leak detection tools to establish and restore leaks promptly.

-

Restoration and Recycling: All the time recuperate and recycle R-410A as a substitute of venting it to the environment.

-

Coaching and Certification: Technicians ought to obtain correct coaching and certification earlier than dealing with R-410A programs.

Conclusion:

The 410A refrigerant pressure-temperature chart is an indispensable device for technicians working with air con and refrigeration programs. Understanding its interpretation, limitations, and the components influencing its accuracy is essential for environment friendly troubleshooting, correct charging, efficiency analysis, and secure operation of R-410A programs. Whereas the chart gives a useful visible illustration of the refrigerant’s conduct, combining it with sensible expertise, superior software program, and adherence to security rules ensures optimum system efficiency and environmental accountability. Do not forget that this info is for academic functions and shouldn’t change skilled coaching and steering. All the time seek the advice of related business requirements and producer specs earlier than endeavor any work on refrigeration or air con programs.

![Free Printable 410A PT Chart Templates [PDF] High Altitude, 53% OFF](https://www.typecalendar.com/wp-content/uploads/2023/08/410A-PT-Chart.jpg)

Closure

Thus, we hope this text has supplied useful insights into Decoding the 410A Refrigerant Strain Chart: A Complete Information. We thanks for taking the time to learn this text. See you in our subsequent article!